What Is a Cream, Gel, & Lotion Manufacturing Plant?

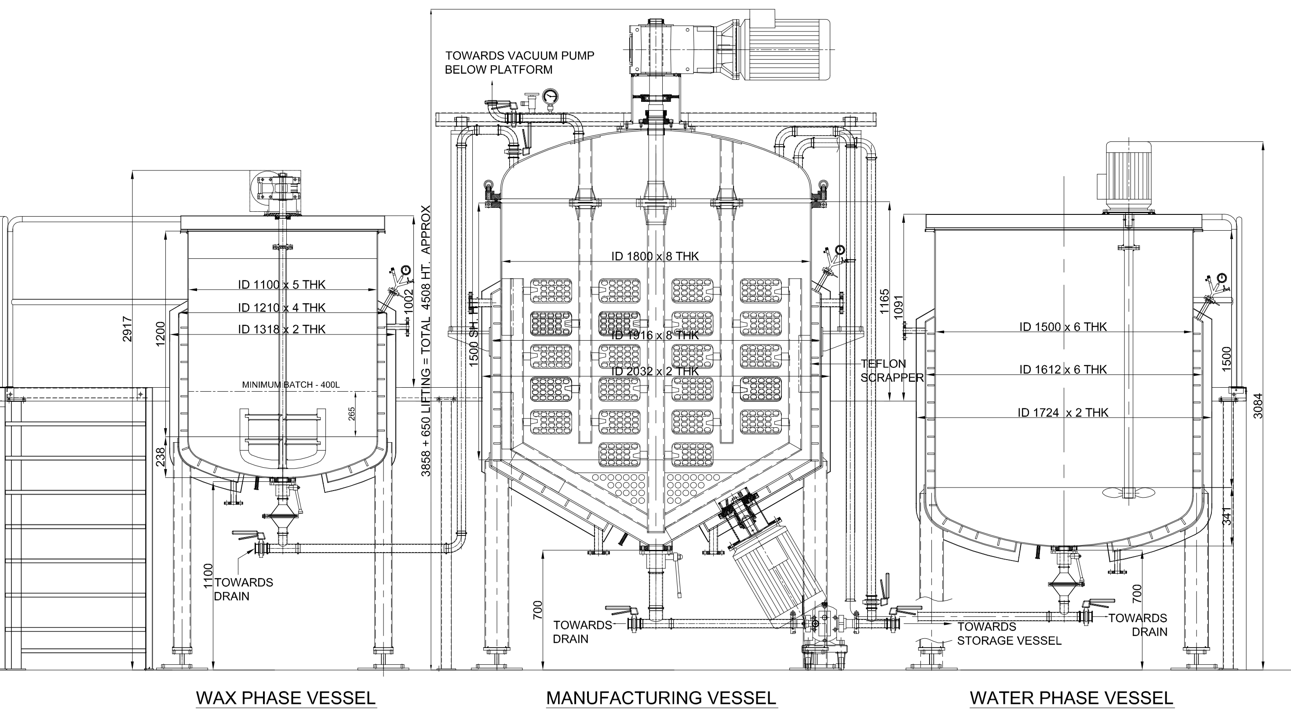

At its core, this manufacturing plant is a specialized assembly of vessels, mixers, control systems, and pipelines designed to produce semi-solid and liquid topical products. Whether you’re making a light body lotion, a rich cream, or a clear gel, the plant is equipped to handle different phases, water phase, oil phase, emulsification, and homogenization, all while maintaining strict hygiene.

Operating under vacuum to minimize entrapped air, heating jackets to control temperature, and high-shear homogenizers for stable emulsions, the plant is geared to deliver smooth, high-quality cosmetics or pharmaceutical creams.

Creams are those preparations that are miscible, immiscible, or emulsified with the skin secretions and intended to be applied to the skin at a specific mucous membrane for emollient, protective, therapeutic, or prophylactic purposes, where a degree of occlusion is desired.

The cream manufacturing plant is built for the manufacture of toothpastes and various other highly viscous products like calamine, Pastes, and other similar products. The cream manufacturing vessel contains various types of equipment and machinery for mixing the ingredients to prepare the final batch. The process of the lotion manufacturing plant starts with mixing ingredients and ends with filling the final product into the storage tubes for marketing.

Working Process

The working principle of a Cream Manufacturing Plant is as follows: first, the hydrophilic ingredients (hydrophilic ingredients are freely soluble in water) are required for producing a specific cream. The water phase vessel is filled with these ingredients. Also, water is added to it. The mechanical mixing method is initiated, and the propeller stirrer is activated to ensure proper mixing. If there is a problem with further mixing, it is done by applying heat. This heat should not be provided directly, but rather in a jacketed manner.

The working of a cream manufacturing plant is quite simple. It takes the ingredients in powder form, and then these are mixed with the wax and water in the respective phase vessel. The operator can control the mixing process, along with the temperature and pressure, during this stage. Then the mixed products are moved to the manufacturing vessel in a vacuum environment. The entire process is completed in a pollution-free manner and allows effective production of large batches of cream.

Components

The Cream Manufacturing Plant contains the following equipment. Which plays a key role in the manufacturing process of cream/gel/lotion, and ointments.

1) Water Phase Vessel

The water phase vessel is the first step in the Cream Manufacturing. In this phase, the water-soluble ingredients are dissolved in water. In addition, a stirrer does the mixing mechanically. Further heating is applied to the mix.

- Jacket for heating & cooling

- Heating Jacket Pressure (4 bar)

- Heating by steam or hot water circulation

- Propeller stirring with top installed

- Temperature controller & safety pressure valve

- Bottom discharge with valve

2) Wax Heating Vessel

The wax heating vessel is the second step in the Lotion Manufacturing. In this stage, the oil and wax type of ingredient is dissolved and melted by heating and a mechanical way of stirrer mixer.

3) Manufacturing Vessel

This is the third step in the Cream Manufacturing. Here, the mixing of both the filtered solvents occurs. Water phase vessel, solvent and oil phase solvent are collected in the manufacturing vessel, and the mixing is started. This mixing is done with the help of a planetary mixer.

The heating and cooling of ingredients are done in a jacketed way. And the jacket is supplied with hot water or steam for heating the ingredients. In addition, for the cooling of ingredients, chilled water is circulated in the jacketed system. Here is a glass window for observation of ingredients. Safety valves are present. The interlock system is present for safety purposes. Temperature regulators are present in this section of the Cream Manufacturing Plant, which control the pressure that is present inside the lotion manufacturing plant.

- Vacuumed process

- Vessel Inside Pressure (-1 /+2 Bar)

- Heating Jacket Pressure (-1 /+6 bar)

- Heating by steam or hot water circulation

- Agitator mixer with self-pressure Teflon scrapper

- Scrapper is working cleanly on both sides

- High-speed homogenizer with a toothed rotor-stator type

- RPM sleeplessly with a variable speed drive for the agitator & homogenizer

- High shear & pressurization of the homogenizer

- Homogenization of high viscosities up to 250000 mPas

- Homogenizer installed in the lower position inclined tilted position of the vessel.

- Top lid with motorized top lid for lifting & lowering

- Safety Interlock process with a limit switch

- Connection for Vacuum, Charging, Eyeglass window, Light glass, CIP, SIP, Pressure gauge & safety valve

4) Vacuum Pump

The function of a vacuum pump is to create a vacuum environment in the vessels. The vacuum pump contains vacuum monitoring and vacuum pump valves.

- Water Ring & Oil Type Vacuum Pump

- Vacuum gauge & vacuum relief valve

5) Interconnecting Pipeline

The function of interconnecting pipelines is the junction of the different vessels for wax and water transfer of products. Through this pipeline system, the recirculation of products in the manufacturing vessel occurs. The interconnected pipes assembly also contains the pipes responsible for creating a vacuum in the system.

- Interconnecting Pipeline of all vessels for the transfer of Water, wax, and products

- Recirculation in manufacturing vessels

- Vacuum connecting pipe

6) Storage Vessel

It is a special type of tank in which cream, gel, lotions, ointment, etc., are stored. It is freely attached and is removable from the Cream Manufacturing Plant. It is freely movable from place to place by its wheels. It is a skid-type structure. Moreover, the lower portion also comes jacketed type, in which the cream preparations can be heated.

- Skid-type storage vessel

- Bottom cone is a Jacket for heating

7) Controls & Visualization

In the Cream Manufacturing Plant, there is a digital display that is operated with an electric supply. The control panel display has a touch screen. The speed of rotation and time adjustment of the product are controlled by these control panels. The temperature and the digital control buttons from the control panel control the coolness of the process. The operation of the vacuum system is also controlled by the control panel. The recording data from different batches is also recorded in the control panel. Control panels, along with the working platform, are the key parts of the cream manufacturing plant.

- Electric controls with digital display

- Optional PLC controls with HMI touch screen

- RPM and Process time entries

- Temperature controls-heat/cool

- Vacuum start- stop

- Integrated data recording for batch

8) Working Platform

- Rigid structure with an anti-slipping embossed plate

- Made from AISI 304

9) Safety Features

- Emergency stop button

- Safety vacuum relief valve & Indicator Gauge

- Safety Pressure Valve

- Limit switch at the top lid