DOCUMENTATION & VALIDATION

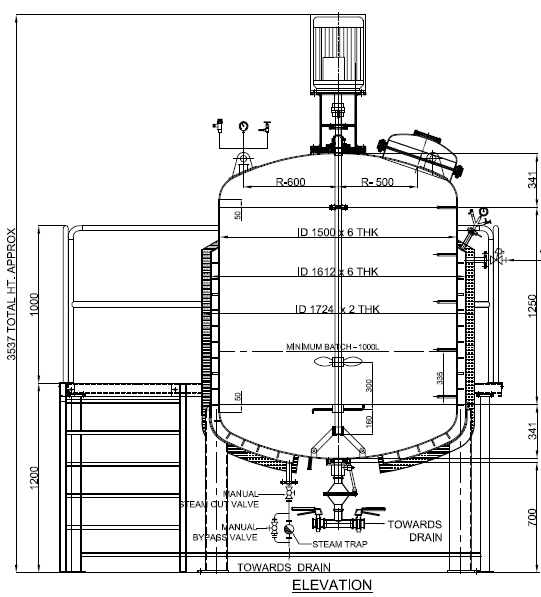

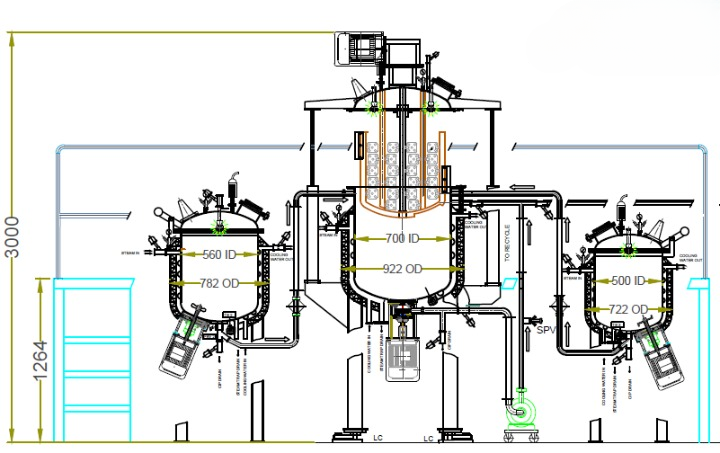

We have our dedicated Quality assurance team ensures delivery of all the required documents like test certificates, MOC, Drawings, P & ID, Weld certificates

Our Quality Assurance team provides close assistance to our customers during their validation cycle, understanding the documentation and validation needs and ensuring the required support.

- General Assembly & P&ID Verification

- Automation Checks

- Documentation Checks