How the Oral Liquid Manufacturing Plant Became a Core Pharmaceutical Need

Imagine a modern pharmaceutical facility in Mumbai & India, preparing to launch a new pediatric syrup. The formulation has been tested, approved, and documented. But the real challenge begins when it’s time to scale it up. Maintaining homogeneity, ensuring no pollutants, achieving accurate temperature control, and guaranteeing consistency from the first litre to the last; that is where the Liquid Oral Processing Plant becomes the heartbeat of the entire process.

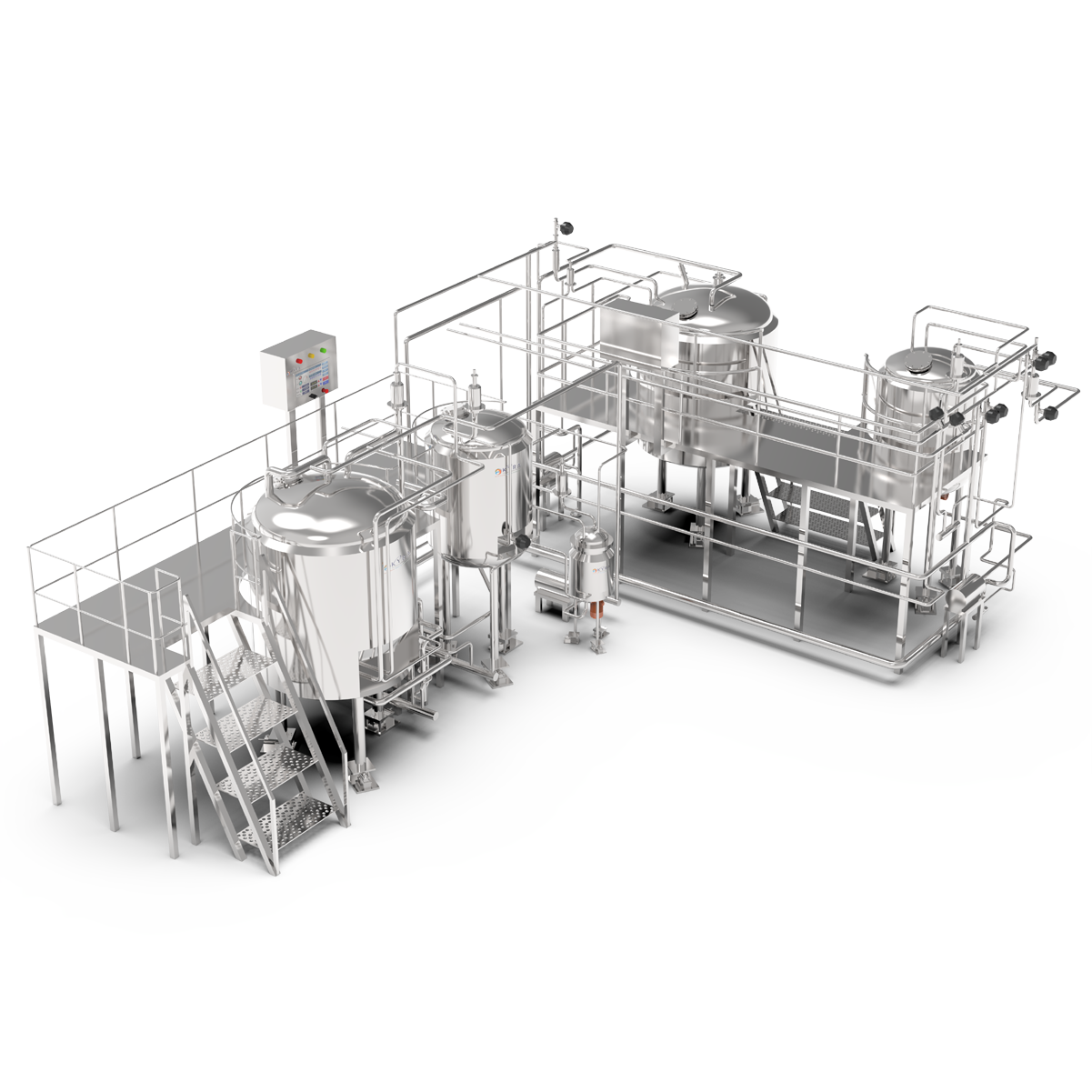

Every vessel, mixer, and transfer pipeline must work in harmony. Every weld must be smooth. Every seal must be hygienic. And every batch must match global quality standards.

This is exactly what Kyra’s plant is designed to deliver - a smooth, sterile, and effective oral liquid manufacturing process.

What Is a Liquid Oral Manufacturing Plant?

A Liquid Oral Processing Plant is a specially designed system used for manufacturing liquid pharmaceutical products such as:

- Syrups

- Suspensions

- Oral solutions

- Antacids

- Vitamin tonics

- Herbal extracts

- Mouthwashes

- Liquid nutraceuticals

It typically includes sugar dissolving vessels, mixing tanks, filtration units, storage vessels, homogenizers, transfer pumps, and CIP/SIP systems, all designed to operate under hygienic and sterile conditions.