What Is a Homogenizer & Mechanical Stirrer?

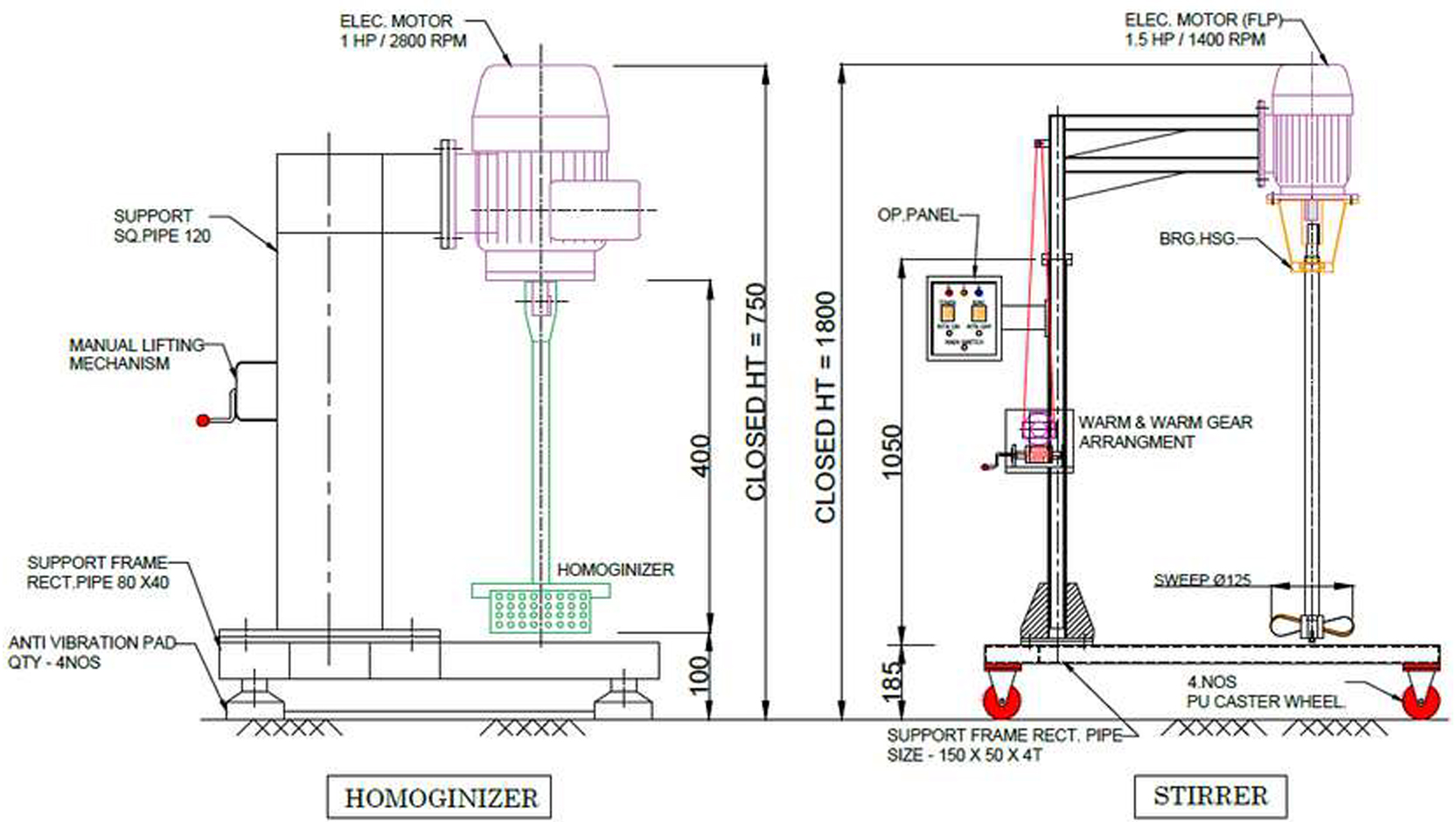

Homogenizers are an important piece of equipment in many types of labs. Everything from tissue, plant, and food samples requires the sample to be broken down before further processing. It consists of types of parts, like the shaft and rotor, for mixing the ingredients to prepare a final product for R&D purposes.

Imagine a pharmaceutical R&D lab in Mumbai, India. Scientists are creating a new injectable or topical product. They begin by mixing APIs, stabilizers, and excipients in a small vessel. But basic mixing isn’t enough; if the formulation isn’t consistent at a microscopic level, it can separate, reduce, or deliver uneven doses. This is where the homogenizer helps. It uses strong mechanical forces to reduce droplet and particle size, forming stable emulsions and dispersions.

Meanwhile, the mechanical stirrer is the main mixer in the vessel. It keeps the batch moving, ensures even heat distribution, and maintains consistency using a motor, shaft, and impeller.

By using both together, Kyra’s systems provide a complete and flexible solution, whether you need gentle mixing or high-shear processing.

Key Features of Homogenizer & Mechanical Stirrer

1. Wide Power Range & Scalability

Our equipment supports a broad power range: from 0.5 HP up to 50 HP for homogenizers, allowing everything from lab-scale to full production capacity.

This range ensures you can scale your process up or down without changing your core mixing technology.

2. Strong, Pharma-Grade Construction

Contact parts are made from stainless steel for strength, corrosion resistance, and hygienic design.

The design follows strict sanitary and GMP standards, making it suitable for pharmaceutical, biotech, cosmetic, food, and chemical processes.

3. High-Shear Homogenization Mechanism

The homogenizer uses a rotor-stator assembly that rotates at high speed, generating shear, turbulence, and cavitation to break down particles.

This mechanism ensures fine emulsions, effective cell disruption (for biotech), or stable suspensions.

4. Flexible Stirring Capabilities

The mechanical stirrer comes with a shaft and impeller design; you can select from a variety of impeller types depending on the nature of your liquid (viscosity, volume, phase).

Speed control and torque are optimized to give you the right mixing power without damaging extraordinary formulations.

5. Accurate Process Control

Motor and drive systems allow variable speed operation, so you can tune the mixing intensity to your formulation needs.

The system can also be integrated with control panels (PLC/HMI) for recipe-based workflows, ensuring batch-to-batch reproducibility.

6. Efficient Cleanability

Designed for easy disassembly where required to improve cleaning and validation.

The use of sanitary stainless-steel construction ensures that surfaces are easy to clean, reducing the risk of product pollutants.

7. Safety & Flexibility

Seals and mechanical components are designed to work effectively even at high speeds, ensuring operator safety.

The unit can be organised for inline or batch processing, depending on your production flow.