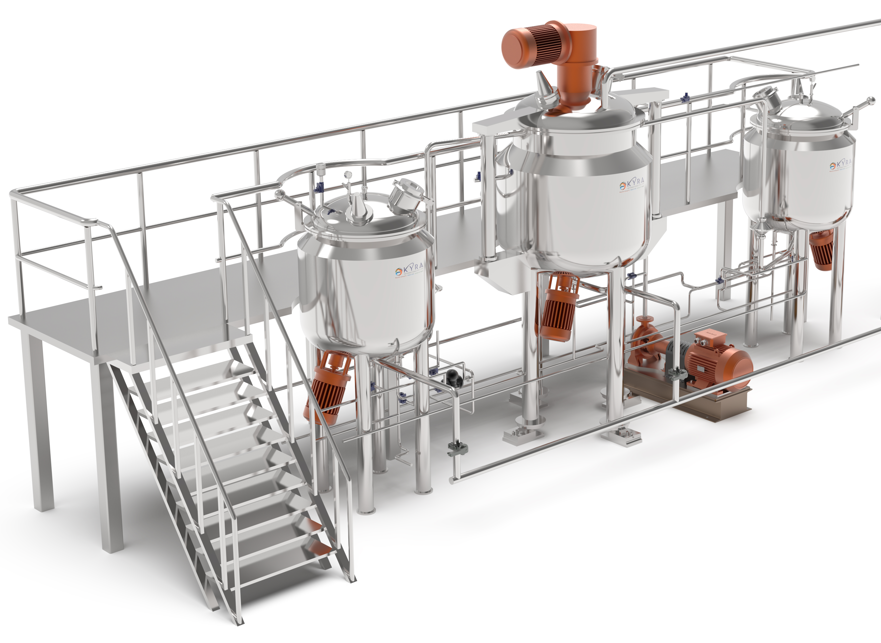

Sterile Injectable Vessels (Processing Skid)

The Sterile manufacturing vessel is suitable for preparing injections, sterile preparations, small volume preparations, inhaler preparations, etc. The sterile manufacturing vessel is used in the pharmaceutical industry to prepare injections, sterile medications, small volume medications, and inhalers. The sterile vessel is manufactured according to the American FDA and WHO standards. The vessel comes with different accessories made for different purposes. The vessel is available with the standard stirrer and magnetic stirrer as per the customer's requirements. Also known as the pharmaceutical sterile manufacturing vessel, it comes with a dish-shaped top and bottom. The top of the vessel has flanged ends and a silicone gasket.

Liquid Oral Processing Plant

The automatic Liquid syrup manufacturing Plant is an ideal tool for the Pharmaceutical and Drugs Industries for the production of Oral Liquids. Liquid Oral Processing plants are designed with the highest quality of fabrication standards using the best components and instruments and it is fully optimized for delivering the best performance with low operating costs.

Cream/Gel/Lotion Manufacturing Plant

Creams are those preparations that are miscible, immiscible, or emulsified with the skin secretions and intended to be applied to the skin at a specific mucous membrane for emollient, protective therapeutic, or prophylactic purposes where a degree of occlusion is desired.

The Cream Manufacturing Plantis built for the manufacture of creams and various other cream-related products like gels, lotions, Pastes,and other similar products. It consists of types of equipment and machinery for mixing the ingredients to form a tube-filling machine. The process of the cream manufacturing plant starts with mixing ingredients and ends with filling the final product in the storage tubes for marketing

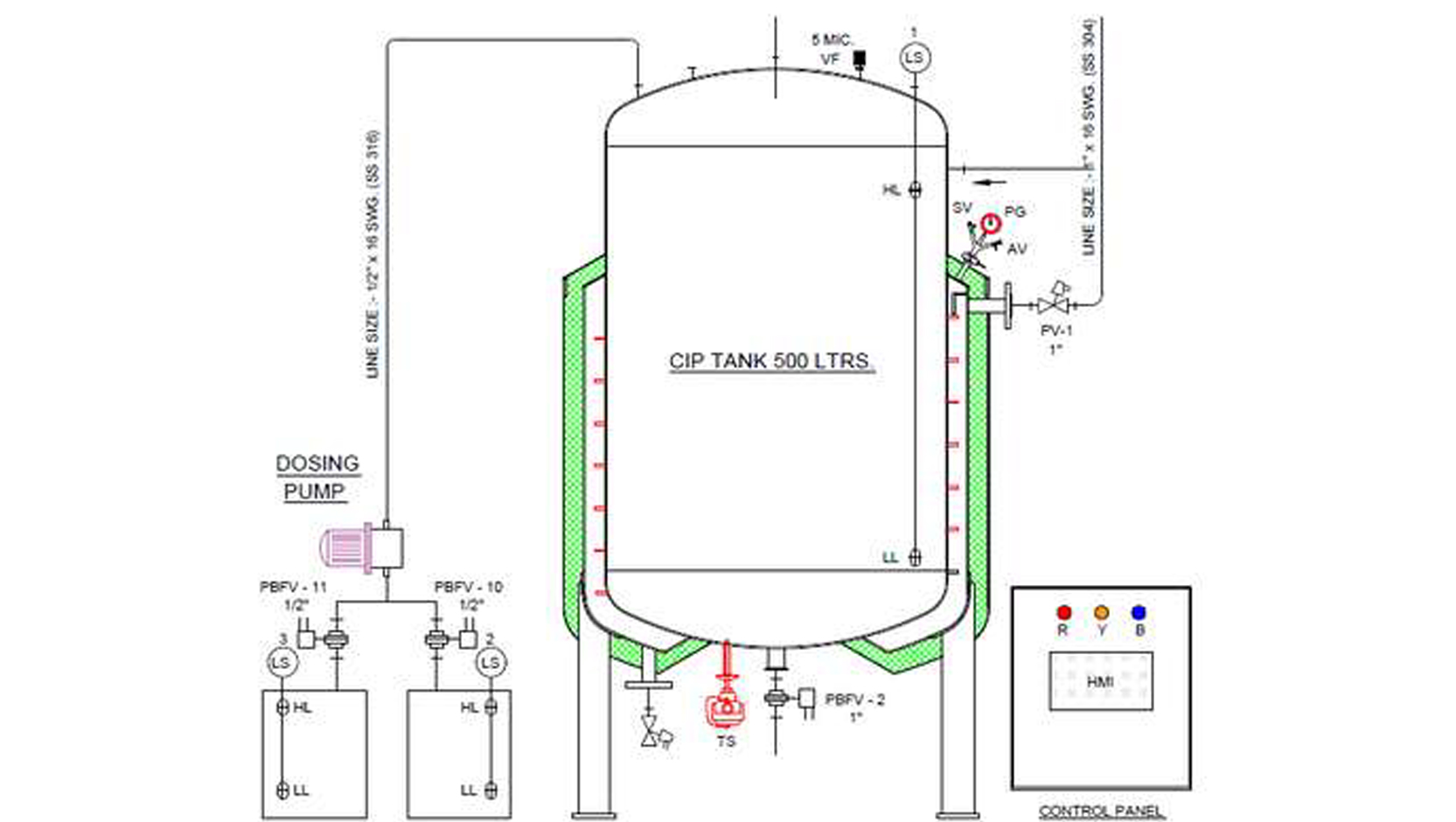

CIP/SIP Skid for Cleaning Manufacturing Plants/vessels

Cleaning-In-Place (CIP) and Sterilization-In-Place (SIP) are systems designed for automatic cleaning and disinfecting without major disassembly and assembly work. We design, develop, manufacture, supply and install Mobile and Fixed CIP & SIP Units for sanitization and sterilization.

The units are custom made, modular, skidded in automated or semi-automated Models as per the required time cycle for cleaning and sterilization as a part of cGMP requirements from portable to large fixed multi-tank system.

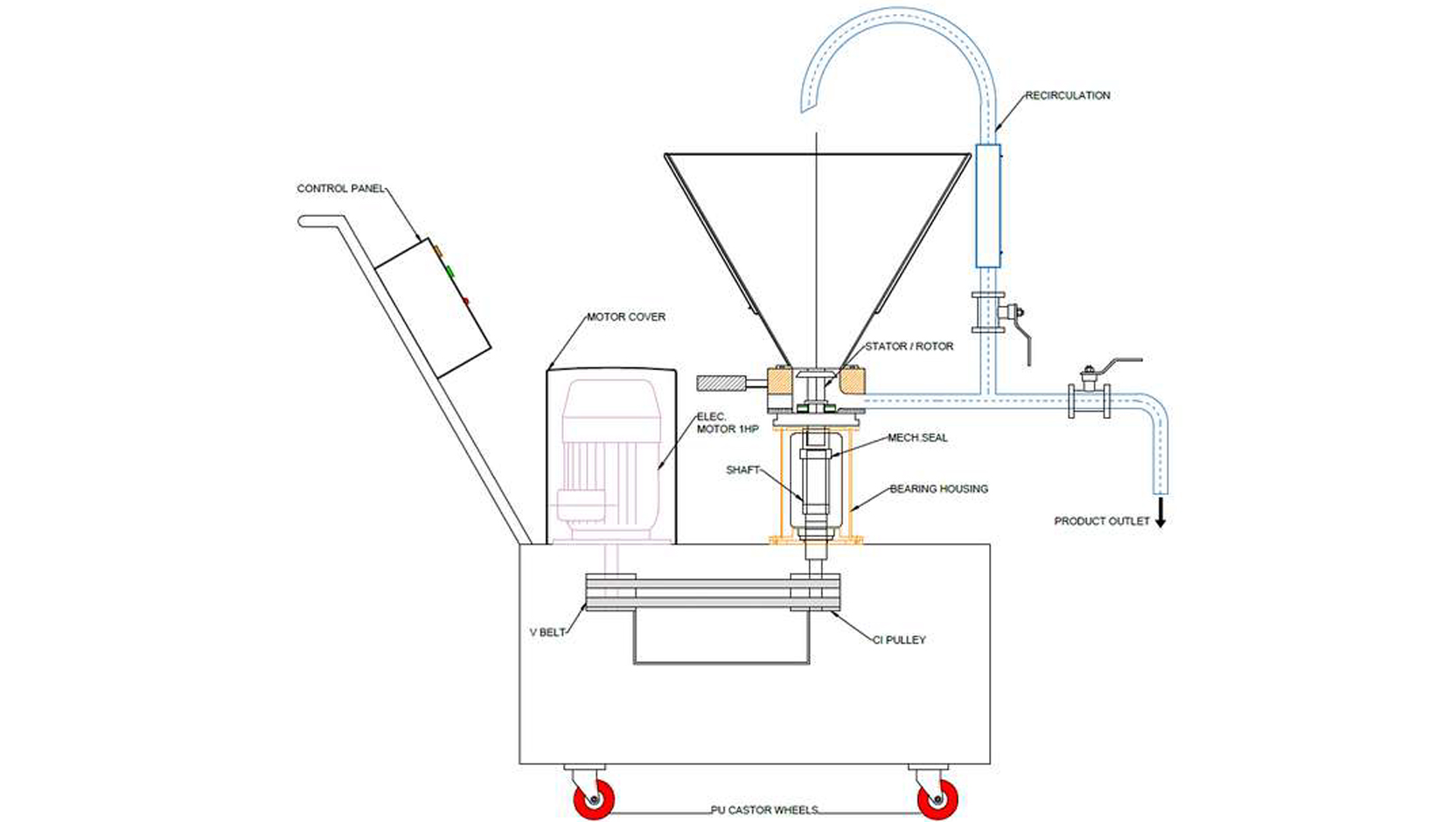

Colloidal Mill

The machine is designed for easy homogenization, emulsification, dispersion, mixing etc. Colloidal mill used for the processing of highly viscous to liquid product in various applications. The principal works on stator/rotor. The product is fed to operating area of rotor which rotates at high speed of approx. 2800rpm, and the product is processed by high shear pressure & friction between stator and rotor.

Due to this the product is exposed to intensive vibrations which exert their force on it by means for pressing & releasing actions. The process for the product is continuous and it can re-circulated if required. The unit can used for small, medium, and large-scale production.

Homogenizer & Mechanical Stirrer

Homogenizers are an essential piece of equipment in many types of labs. Everything from tissue, plant, and food samples require the sample be broken down before further processing. It consists types of parts like shaft and rotor for mixing the ingredients to prepare a final product for R & D purpose.

Gearing your company through an Innovative strategy

Building No 1, Shripal One, 313, Golani Naka, Vasai East, Mumbai, Maharashtra 401208

Phone: +91 99608 88136

+91 80875 88854