In the complex world of pharmaceutical and food manufacturing, cleanliness isn’t just a requirement; it’s a promise. A promise of safety, purity, and trust. Behind that promise lies one of the most innovative engineering systems of modern industry, the SIP/CIP Skid Plants & Vessels.

At Kyra International, a top SIP/CIP skid plant and vessel manufacturer, supplier, and exporter in Mumbai, India, this promise is more than a process; it’s a passion built into every design, every weld, and every automated system they create.

The Story Behind SIP/CIP: Where Accurate Meets Purity

Before automation and expertise in stainless steel were combined, cleaning industrial vessels was a manual, time-consuming, and faulty task. But the rise of Clean-in-Place (CIP) and Sterilize-in-Place (SIP) systems changed the story.

Imagine a pharmaceutical reactor or a food-grade storage tank that can clean and sterilize itself, no disassembly, no human contact, no pollutant risk. That’s the power of SIP and CIP.

CIP (Clean-in-Place) systems use automated cleaning solutions, water, acid, or caustic, circulated through process lines, tanks, and equipment without disassembly.

SIP (Sterilize-in-Place) systems go a step further, using steam or hot water to sterilize surfaces, ensuring a hygienic environment ready for the next production cycle.

These systems have become important for industries like pharmaceuticals, food & beverages, dairy, cosmetics, and biotechnology, where hygiene and effectiveness define success.

Kyra International: Launching SIP/CIP Skid Plants & Vessels

Based in Mumbai, India, Kyra International stands as a leading manufacturer, supplier, and exporter of SIP/CIP skid plants and vessels, with decades of engineering excellence and process innovation.

Their expertise goes beyond just fabrication, but also in understanding the science of cleanliness and automation-driven consistency. Every plant is custom-engineered, ensuring smooth integration with the client’s process requirements.

Why Kyra International Leads the Industry?

- Customized Engineering: Modified SIP/CIP solutions designed for specific process applications and plant sizes.

- Capacity Flexibility: Systems available from 5L to 5000L, delivering to small-scale R&D setups and large-scale industrial production.

- Advanced Automation: PLC/SCADA-based systems ensure accurate cleaning and sterilization cycles.

- Hygienic Design: Use of SS 316L and other sanitary-grade materials with mirror-polished internal surfaces.

- Compliance Guarantee: Systems follow to FDA, GMP, and ASME standards.

- Energy Effectiveness: Optimized chemical and water consumption with sustainable design.

Kyra International combines flow meters, temperature sensors, and conductivity analysers to ensure every cleaning step is confirmed. Their skid plants can handle multiple cleaning circuits together, reducing downtime and increasing production efficiency.

Breaking Down the SIP/CIP Skid System: Components That Make a Difference

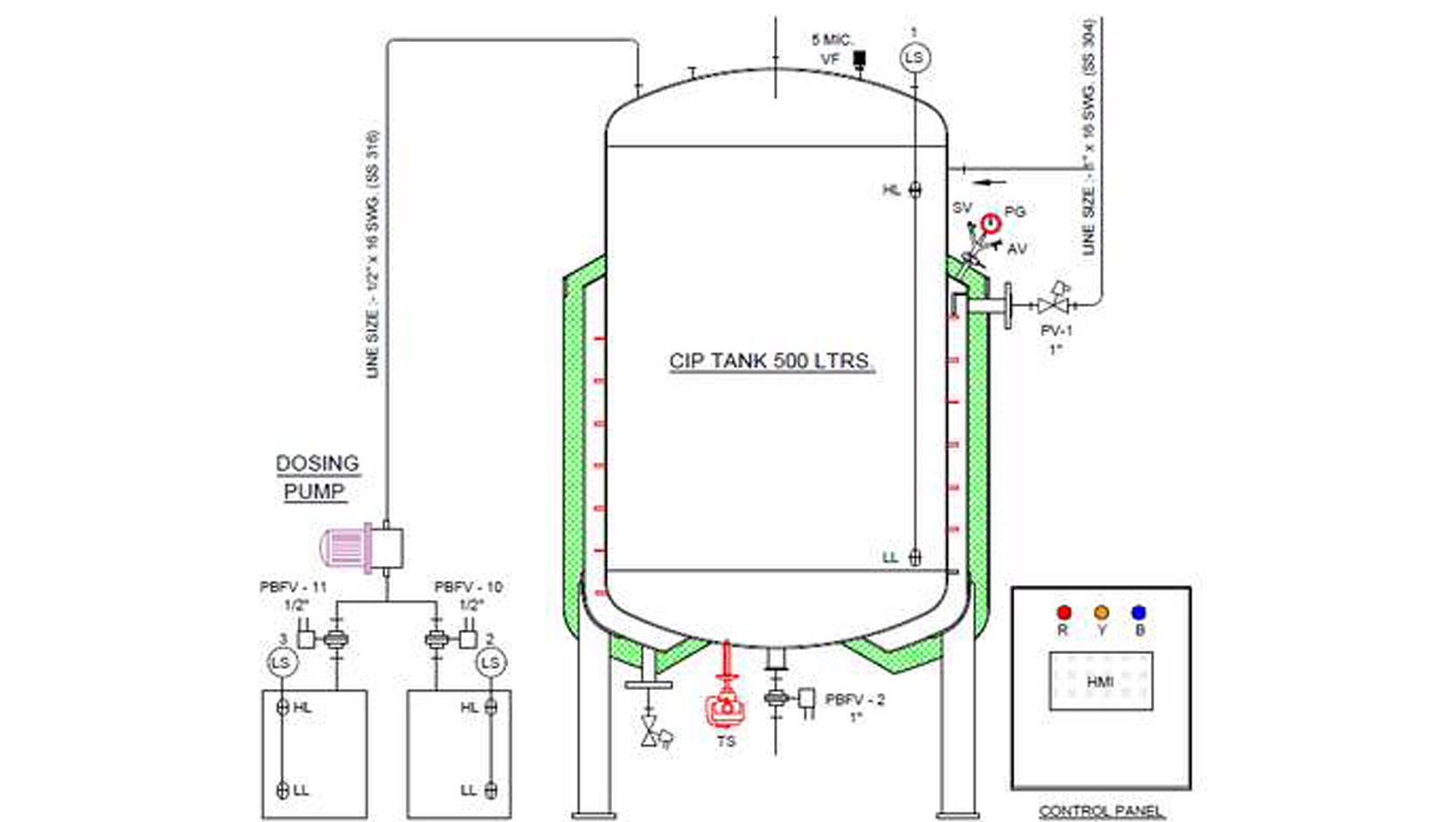

A typical CIP/SIP Skid Plant from Kyra International includes:

- Storage Tanks: For water, caustic, and acid solutions.

- Pumps and Valves: To regulate flow and pressure.

- Heat Exchangers: To maintain accurate temperature control during cleaning.

- Automation Panel (PLC/SCADA): For full cycle control, data logging, and validation reports.

- Piping Network: Designed with hygienic fittings and tri-clamp joints for easy maintenance.

Each component is carefully engineered to offer maximum efficiency and zero impurity; available in a wide capacity range from 5L to 5000L to suit different industry requirements.

Applications Across Industries

1. Pharmaceutical & Biotech

- Ensures sterile production environments for injectable drugs, syrups, and vaccines.

- Kyra International’s SIP systems guarantee microbial-free equipment, following cGMP standards.

2. Food & Beverage

- From dairy processing to soft drinks, CIP systems help maintain product integrity, preventing cross-contamination.

3. Cosmetics & Personal Care

- Cleans mixing and storage tanks used for lotions, creams, and gels without manual breaking in.

4. Chemical Processing

- Automated cleaning reduces downtime and the risk of chemicals remaining in the following batches.